Project Overview

Location: Far Eastern Region, Russia

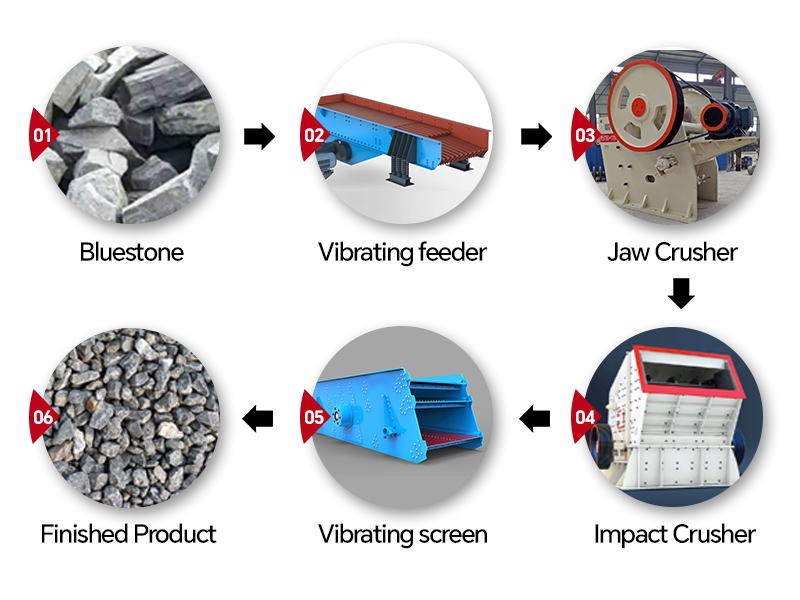

Process Flow

1. Primary Crushing

Large bluestone blocks are continuously fed from the storage bin to the jaw crusher via a vibrating feeder. The jaw crusher crushes the bluestone through repeated compression and impact, reducing it to small-sized particles.

2. Secondary Crushing

Coarsely crushed bluestone particles from the jaw crusher enter an impact crusher (or hammer crusher) for fine grinding, producing smaller particles.

3. Screening

The finely crushed particles are conveyed by belt to a circular vibrating screen. Non-compliant oversized particles are returned to the impact crusher (or hammer crusher) for reprocessing.

4. Closed-Loop System

Qualified particles are transported to the finished product stockpile, completing a closed-circuit recycling process.

Key Advantages

1. Optimized Layout

Compact and logical production line configuration

Smooth operational stability

2. Simplified Maintenance

Streamlined process design reduces downtime

Easy access for routine servicing

3. Cost Efficiency

Low operating costs

Rapid return on investment

4. Eco-Friendly Operation

Low noise levels (<85 dB)

Minimal dust emission

Emergency:

+86 18820104928Copyright © 2025 Guangzhou Future Green Machinery Co., Ltd. All Right Reserved.

Network SupportedXML Privacy Policy

Network SupportedXML Privacy Policy