Project Overview

Location: Astana, Kazakhstan

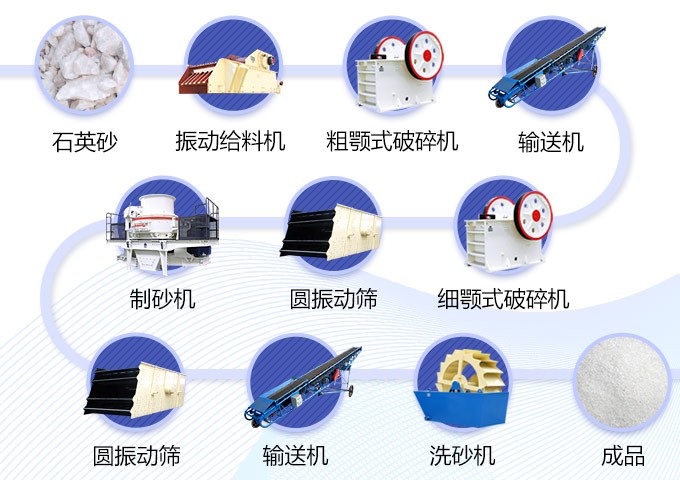

Process Flow

1. Crushing Stage

• Raw quartz ore is continuously fed into a primary jaw crusher via vibrating feeder

• Crushed material conveyed to secondary jaw crusher for fine crushing

• Processed material screened by circular vibrating screen

2. Sand Making Stage

• Screen-sorted quartz particles meeting feed size requirements enter sand making machine

• Oversized particles return to crushers for reprocessing

3. Screening Stage

• Processed sand returns to vibrating screen for final grading:

✓ Qualified material proceeds to washing

✓ Substandard material recycles to sand maker

4. Washing Stage

• Finished sand conveyed to washer for cleaning

• Cleaned product transferred to storage pile

Key Advantages

1. Reliable Configuration

• Optimized equipment layout with wear-resistant components

• Advanced manufacturing ensures extended service life

2. Cost Efficiency

• Ultra-low failure rate reduces downtime

• Energy consumption decreased by >50%

3. Eco-Friendly Production

• Pulse dust collector eliminates airborne particles

• Fully enclosed design minimizes environmental impact

4. Economic Value

• Cost-effective initial investment

• Comprehensive after-sales service support

Emergency:

+86 18820104928Copyright © 2025 Guangzhou Future Green Machinery Co., Ltd. All Right Reserved.

Network SupportedXML Privacy Policy

Network SupportedXML Privacy Policy