Compatible with Atlas Copco/Epiroc giant drill iron frame model giant drill iron castings for underground drilling

✅ Audited Supplier

✅ Importers and Exporters

✅ High Repeat Buyers Choice

✅ Fast Delivery

✅ OEM Services

Item No :

FG3128078438Order(MOQ) :

1Product Origin :

ChinaLead Time :

15 daysContact :

+86 18820104928The unique design of the piston generates a perfect, long shock wave of a trapezoidal shape:

Underground mining equipment

Product Advantages

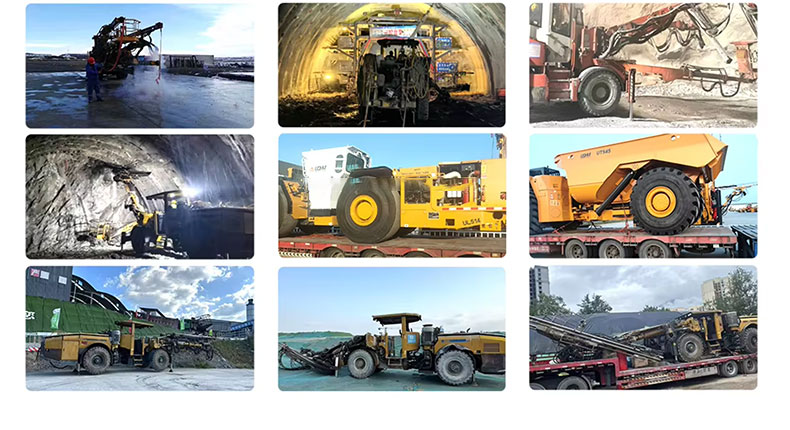

The drilling rig is mainly suitable for tunnel construction, underground mining and other underground projects. It can be used for drilling blast holes, anchor holes, slot holes. There is also an available platform that can be used to install explosives, anchors and other equipment. The maximum coverage area is up to 72 square meters.

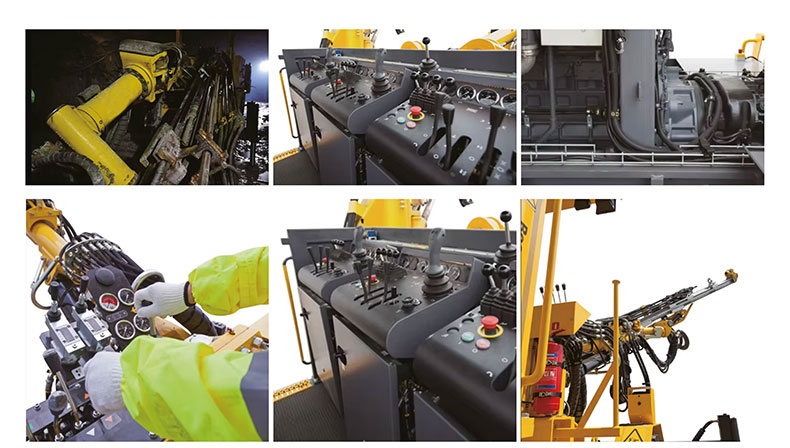

1. Power system Located in the middle of the frame, it is mainly composed of a diesel engine, a radiator, a firewood box, an air filter, an exhaust purification device, a fuel filter, an oil filter, etc. In addition to providing power for driving and braking during driving, it can also provide power for other actions except rock drill impact and rotation. 2. Drive system Mainly composed of front and rear axles, tires, gearboxes, drive shafts, etc., it is mainly used for walking. The drive system converts the engine power into the power of the walking vehicle, while meeting the braking requirements. Standard wet bridge. 3. Frame It is mainly divided into three parts: the front frame and the rear end. The front frame and the frame are hingedly connected with a vertical pin shaft, which can complete the articulated steering function of the vehicle; the front and rear legs are used for vehicle leveling giant drilling operations; in addition to the cable drum bracket, etc., under the frame of the transmission system, the frame also bears the main structure of each component. 4. Boom Fixed by the drill arm, triangular cylinder, square welded rear boom, tile-covered rectangular welded cylinder telescopic arm, front triangle, triangular installation front welding, rotating cylinder, welding body and pushing beam welding steering arm bracket, etc.; the fixed seat can connect the arm drill arm, the rear of the triangular cylinder is connected with the front cylinder through the hydraulic system to achieve the function of parallel drill arm maintenance; the bracket for installing the thruster, the rotating cylinder can make the drive shaft rotate 360 °.

CASE STUDIES FROM VARIOUS INDUSTRIES

Emergency:

+86 18820104928Copyright © 2025 Guangzhou Future Green Machinery Co., Ltd. All Right Reserved.

Network SupportedXML Privacy Policy

Network SupportedXML Privacy Policy